Difference between revisions of "Disorient Plastic Recycling"

| (26 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

Cell Lead: The Eye<BR> | Cell Lead: The Eye<BR> | ||

[[Image:20240329.DisorientPlasticRecyclingLogoBlack.4500px.png|400px]] | |||

==On-Site Mixed-Plastic Recycling== | ==On-Site Mixed-Plastic Recycling== | ||

After all these years, words and good intents, we are still in what feels like the Stone Age of plastic recycling. A long-term solution demands that we break the table-to-landfill cycle and weave plastic recycling deep into our lives by turning it into a practice, a ritual.<BR> | After all these years, words and good intents, we are still in what feels like the Stone Age of [https://en.wikipedia.org/wiki/Plastic_recycling plastic recycling]. A long-term solution demands that we break the table-to-landfill cycle and weave plastic recycling deep into our lives by turning it into a practice, a ritual.<BR> | ||

===Progress Report and Updates=== | |||

<b>20240404</b>: During our chat at the Sun Contemporary gallery opening in Bali, Sam (founder of [https://sungai.watch Sungai Watch] with more than 2000 tons of plastic collected to date in Indonesia and counting) recommends separating plastics before compressing them. His argument is that once plastics are mixed, they are no longe recyclable. There are dozens of different types of plastic out there but only about 7 main ones in Bali which makes sorting relatively easy. In his experience, plastic bags are one of the most common. It is not easy to identify the different types of hard plastics.<BR> | |||

<b>20240310</b>: IceCream warns about poison released when melting plastic.<BR> | |||

===Here's our plan=== | ===Here's our plan=== | ||

1. <b>Keep it simple</b>.<BR> | 1. <b>Keep it simple</b>.<BR> | ||

1.1. <b>Use what's readily available</b>. The chosen recycling process should not require water, chemicals, additives, adhesives, or fillers. Ultimately, it should not require electricity either but we will probably use some electricity at the beginning to jumpstart the process.<BR> | 1.1. <b>Use what's readily available</b>. The chosen recycling process should not require water, chemicals, additives, adhesives, or fillers. Ultimately, it should not require electricity either but we will probably use some electricity at the beginning to jumpstart the process.<BR> | ||

1.2. <b>Minimal pre-processing</b>. We need to find ways to make recycling entertaining and intellectually rewarding, in other words, we need to amplify its feel-good factor and make it viral. Developing a recycling practice should be as easy as possible with only minimal sorting, cleaning or pre-processing. There are arguments for pre-processing but at our stage of recycling (remember, we're in the Stone Age) we just need to keep it simple get started. We can get fancy later.<BR> | 1.2. <b>Minimal pre-processing</b>. We need to find ways to make recycling entertaining and intellectually rewarding, in other words, we need to amplify its feel-good factor and make it viral. Developing a recycling practice should be as easy as possible with only minimal sorting, cleaning or pre-processing. There are arguments for pre-processing (see below) but at our stage of recycling (remember, we're in the Stone Age) we just need to keep it simple to get started. We can get fancy later.<BR> | ||

During our chat at the Sun Contemporary gallery opening on 20240404 in Bali, Sam (founder of [https://sungai.watch Sungai Watch] with more than 2000 tons of plastic collected to date in Indonesia and counting) recommends separating plastics before compressing them. His argument is that once plastics are mixed, they are no longe recyclable. There are dozens of different types of plastic out there but only about 7 main ones in Bali which makes sorting relatively easy. In his experience, plastic bags are one of the most common. It is not easy to identify the different types of hard plastics.<BR> | |||

2. <b>On-site, on-scale and self-reliant</b>. The transportation of discarded plastics accounts for a large part of plastic-related pollution. Ironically, current recycling strategies involve polluting the air further by shipping huge amounts of trash around the planet. Following our DIY ethos, plastics recycled by Disorient is not moved to another facility across the planet or even across the playa. It is reconfigured on site with a solution tailored to our problem.<BR> | 2. <b>On-site, on-scale and self-reliant</b>. The transportation of discarded plastics accounts for a large part of plastic-related pollution. Ironically, current recycling strategies involve polluting the air further by shipping huge amounts of trash around the planet. Following our DIY ethos, plastics recycled by Disorient is not moved to another facility across the planet or even across the playa. It is reconfigured on site with a solution tailored to our problem.<BR> | ||

3. <b>Distributed</b>. To have a better chance to reduce our contribution to the landfill, plastic recycling needs to become easy, hyper-local and sexy. Based on point #2 above, the solution should be open-source and easily replicable by other individuals/camps/communities. The current centralized industrial solutions need to be balanced and possibly replaced with decentralized individual solutions. We need to address the problem where it happens: in everyone's backyard. Small solutions distributed widely.<BR> | 3. <b>Distributed</b>. To have a better chance to reduce our contribution to the landfill, plastic recycling needs to become easy, hyper-local and sexy. Based on point #2 above, the solution should be open-source and easily replicable by other individuals/camps/communities. The current centralized industrial solutions need to be balanced and possibly replaced with decentralized individual solutions. We need to address the problem where it happens: in everyone's backyard. Small solutions distributed widely.<BR> | ||

| Line 15: | Line 23: | ||

===Shredding=== | ===Shredding=== | ||

The first step of the process is to break-down plastic objects to be recycled into little chips. For this, we need a shredder.<BR> | The first step of the process is to break-down plastic objects to be recycled into little chips. For this, we need a shredder.<BR> | ||

The shredding part of the process requires more investment since the shredder itself is a relatively expensive piece of equipment [https://www.alibaba.com/product-detail/High-powered-plastic-shredder-Injection-mouth_1600621913929.html starting around 1,000 USD] in Asia and [https://www.bing.com/shop?q=Plastic-Shredder-Machine-Granulator&FORM=SHOPTB around 2,000 USD] in the US.<BR> | The shredding part of the process requires more investment since the shredder itself is a relatively expensive piece of equipment [https://www.alibaba.com/product-detail/High-powered-plastic-shredder-Injection-mouth_1600621913929.html starting around 1,000 USD] in Asia and [https://www.bing.com/shop?q=Plastic-Shredder-Machine-Granulator&FORM=SHOPTB around 2,000 USD] in the US.<BR> | ||

====Plastic Shredder==== | ====Our first Plastic Shredder==== | ||

<b>20240315</b>: We have selected and purchased [https://www.amazon.com/dp/B0CLHSGKVH?th=1 this shredder]. DPR goes live at [[Disorient presents: CCXII - Possibilities of Pattern|CCXii]] upstate NY at the end of May.<BR> | |||

====Early research on shredders==== | |||

We use a plastic shredder like [https://www.tokopedia.com/ppmachine/shredder-machine-mesin-pencacah-mesin-penghancur-precious-plastic?utm_source=whatsapp&utm_medium=share&utm_campaign=PDP-155063182-573675700-311022-contextual_image this one (Tokopedia, Indonesia)] or [https://www.amazon.com/gp/product/B0C9BZBL4S/ref=ewc_pr_img_1?smid=A2UP4SV2PZJ5KZ&th=1 that one (Amazon, USA)] to turn mixed plastics into chips.<BR> | We use a plastic shredder like [https://www.tokopedia.com/ppmachine/shredder-machine-mesin-pencacah-mesin-penghancur-precious-plastic?utm_source=whatsapp&utm_medium=share&utm_campaign=PDP-155063182-573675700-311022-contextual_image this one (Tokopedia, Indonesia)] or [https://www.amazon.com/gp/product/B0C9BZBL4S/ref=ewc_pr_img_1?smid=A2UP4SV2PZJ5KZ&th=1 that one (Amazon, USA)] to turn mixed plastics into chips.<BR> | ||

| Line 56: | Line 65: | ||

===Which new plastic objects do we need?=== | ===Which new plastic objects do we need?=== | ||

Making objects out of plastic | Making objects out of plastic waste is neat but the question at the end of the recycling line is this: what kind of new plastic objects do we need? What objects are best positioned to gain the most from being made out of plastic? How do we avoid recycling the problem along with the plastic?<BR> | ||

Disorient's goal is not only to become self-reliant when it comes to plastic recycling by recycling on-site (immediacy) but also to start using the resulting plastic bricks (and possibly other objects depending on the molds used during compression) as a component of our art installations. Creating [https://en.wikipedia.org/wiki/3D_printing_filament 3D printing filaments] is a possible solution but requires specific types of plastics which means that we would need to add pre-processing steps to our plastic recycling. This is something that we are trying to avoid at the beginning.<BR> | Disorient's goal is not only to become self-reliant when it comes to plastic recycling by recycling on-site (immediacy) but also to start using the resulting plastic bricks (and possibly other objects depending on the molds used during compression) as a component of our art installations. Creating [https://en.wikipedia.org/wiki/3D_printing_filament 3D printing filaments] is a possible solution but requires specific types of plastics which means that we would need to add pre-processing steps to our plastic recycling. This is something that we are trying to avoid at the beginning.<BR> | ||

| Line 62: | Line 71: | ||

It's somewhat comforting to know that when our recycled plastic objects become obsolete, we can throw them back into the shredder for another cycle.<BR> | It's somewhat comforting to know that when our recycled plastic objects become obsolete, we can throw them back into the shredder for another cycle.<BR> | ||

None of this is new. What's new is to actually make it happen.<BR> | None of this is new. What's new is to actually make it happen locally.<BR> | ||

[[ | References:<BR> | ||

<I>[https://sungaidesign.com/products/the-ripple-lounge-black Ombak Lounger]</I>. A chair by [https://www.merkabadesigns.com/my-projects/sungai-design Merkaba Designs] for [http://sungaidesign.com Sungai Design]<BR> | |||

<I>[https://plaex.ca PLAEX bricks]</I>. Interlocable building system based on Lego-inspired building blocks fabricated with a mix of thermoplastic and waste construction aggregates. This new material called [https://plaex.ca/plaex-crete PLAEX-crete] looks and feel like concrete.<BR><BR><BR><BR><BR><BR><BR><BR><BR><BR> | |||

[[Image:D22JerryJamesStopBurningSht.jpg|center|300px]]<BR> | |||

“STOP BURNING SH*T” T-shirt<BR> | |||

D22 camper and co-builder of the first Man at the first Burning Man event at San Franciscos's Baker Beach in 1986, Jerry James inspires a new wave of non-burnable art.<BR> | |||

[[Image:20240329.DisorientRecyclingLogo.3000px.png|right|100px]] [[Image:20240329.DisorientRecyclingLogoBlack.3000px.png|right|100px]] | |||

===Banner=== | |||

DPR [[Banners|banner]] goes here. | |||

Latest revision as of 04:50, 9 May 2024

Disorient Plastic Recycling aka DPR (pronounced deeper)

Cell Lead: The Eye

On-Site Mixed-Plastic Recycling

After all these years, words and good intents, we are still in what feels like the Stone Age of plastic recycling. A long-term solution demands that we break the table-to-landfill cycle and weave plastic recycling deep into our lives by turning it into a practice, a ritual.

Progress Report and Updates

20240404: During our chat at the Sun Contemporary gallery opening in Bali, Sam (founder of Sungai Watch with more than 2000 tons of plastic collected to date in Indonesia and counting) recommends separating plastics before compressing them. His argument is that once plastics are mixed, they are no longe recyclable. There are dozens of different types of plastic out there but only about 7 main ones in Bali which makes sorting relatively easy. In his experience, plastic bags are one of the most common. It is not easy to identify the different types of hard plastics.

20240310: IceCream warns about poison released when melting plastic.

Here's our plan

1. Keep it simple.

1.1. Use what's readily available. The chosen recycling process should not require water, chemicals, additives, adhesives, or fillers. Ultimately, it should not require electricity either but we will probably use some electricity at the beginning to jumpstart the process.

1.2. Minimal pre-processing. We need to find ways to make recycling entertaining and intellectually rewarding, in other words, we need to amplify its feel-good factor and make it viral. Developing a recycling practice should be as easy as possible with only minimal sorting, cleaning or pre-processing. There are arguments for pre-processing (see below) but at our stage of recycling (remember, we're in the Stone Age) we just need to keep it simple to get started. We can get fancy later.

During our chat at the Sun Contemporary gallery opening on 20240404 in Bali, Sam (founder of Sungai Watch with more than 2000 tons of plastic collected to date in Indonesia and counting) recommends separating plastics before compressing them. His argument is that once plastics are mixed, they are no longe recyclable. There are dozens of different types of plastic out there but only about 7 main ones in Bali which makes sorting relatively easy. In his experience, plastic bags are one of the most common. It is not easy to identify the different types of hard plastics.

2. On-site, on-scale and self-reliant. The transportation of discarded plastics accounts for a large part of plastic-related pollution. Ironically, current recycling strategies involve polluting the air further by shipping huge amounts of trash around the planet. Following our DIY ethos, plastics recycled by Disorient is not moved to another facility across the planet or even across the playa. It is reconfigured on site with a solution tailored to our problem.

3. Distributed. To have a better chance to reduce our contribution to the landfill, plastic recycling needs to become easy, hyper-local and sexy. Based on point #2 above, the solution should be open-source and easily replicable by other individuals/camps/communities. The current centralized industrial solutions need to be balanced and possibly replaced with decentralized individual solutions. We need to address the problem where it happens: in everyone's backyard. Small solutions distributed widely.

4. Start with Disorient. In recent years Disorient camp at Burning Man has welcomed about 230 campers per year. Our plan is to create a recycling system that will be able to address the mixed-plastics recycling needs of all our campers.

Shredding

The first step of the process is to break-down plastic objects to be recycled into little chips. For this, we need a shredder.

The shredding part of the process requires more investment since the shredder itself is a relatively expensive piece of equipment starting around 1,000 USD in Asia and around 2,000 USD in the US.

Our first Plastic Shredder

20240315: We have selected and purchased this shredder. DPR goes live at CCXii upstate NY at the end of May.

Early research on shredders

We use a plastic shredder like this one (Tokopedia, Indonesia) or that one (Amazon, USA) to turn mixed plastics into chips.

We plan to start with a shredder rather than a granulator. Granulator vs shredder: what is the difference?

Some US companies that provide industrial shredders (for reference only since we will start with a shredder smaller than the ones those companies provide): Lanrryy Machinery, Franklin Miller, Vecoplan

Example of plastic shredder at the Museum of Space Available, Bali, Indonesia, 2022:

Compressing

Then we use a compressor with a mold to compress the plastic chips into bricks similar to this one or that one to create bricks following this example.

Compression can be achieved with a simple car jack. The compression mold is a relatively affordable one-time investment. Using a 2 ton press will work ok. A 10 ton press will probably give better result. What happens if we use a 4000 ton press to create our plastic bricks?

Pressure equals heat. Solar heat can be used to soften/melt the plastic chips to help the compressing process. For instance we could leverage the heat stored by a large metal object such as a shipping container exposed to the sun to melt the shreds of plastic into metal molds. In the desert, we could also explore solar ovens.

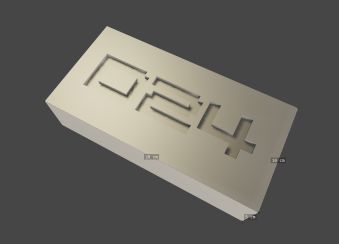

Our first brick

Recycled plastic brick

"D24" debossed on one side

Dimensions: 20cm x 10cm x 5cm

Brick Compressor

Examples of brick compressor and molds

Human-powered recycling set

Example of human-powered plastic shredder and brick compressor at Monsieur Spoon in Pererenan, Bali, Indonesia, August 2020:

Although not our approach, here's a video of a radical experiment of melting mixed plastics together.

Which new plastic objects do we need?

Making objects out of plastic waste is neat but the question at the end of the recycling line is this: what kind of new plastic objects do we need? What objects are best positioned to gain the most from being made out of plastic? How do we avoid recycling the problem along with the plastic?

Disorient's goal is not only to become self-reliant when it comes to plastic recycling by recycling on-site (immediacy) but also to start using the resulting plastic bricks (and possibly other objects depending on the molds used during compression) as a component of our art installations. Creating 3D printing filaments is a possible solution but requires specific types of plastics which means that we would need to add pre-processing steps to our plastic recycling. This is something that we are trying to avoid at the beginning.

It's somewhat comforting to know that when our recycled plastic objects become obsolete, we can throw them back into the shredder for another cycle.

None of this is new. What's new is to actually make it happen locally.

References:

Ombak Lounger. A chair by Merkaba Designs for Sungai Design

PLAEX bricks. Interlocable building system based on Lego-inspired building blocks fabricated with a mix of thermoplastic and waste construction aggregates. This new material called PLAEX-crete looks and feel like concrete.

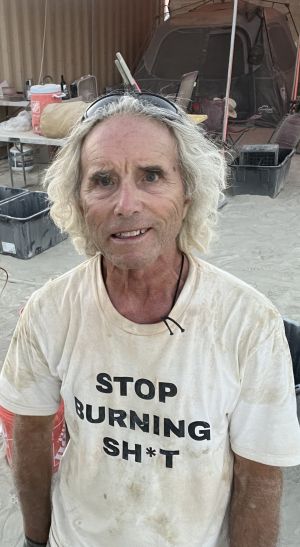

“STOP BURNING SH*T” T-shirt

D22 camper and co-builder of the first Man at the first Burning Man event at San Franciscos's Baker Beach in 1986, Jerry James inspires a new wave of non-burnable art.

Banner

DPR banner goes here.